Buitoni pizza scandals, Nestlé mineral water contaminations, or more recently the presence of pathogens in Perrier products… Despite living in a world where technology is almost everywhere, health crises in the food industry are on the rise.

Yet, quality controls in the food industry are mandatory and must comply with strict standards. So where do these failures come from? From a lack of traceability! Too often, food companies still track their quality procedures on paper or Excel. To prevent health issues, digitalizing quality controls in the food industry is the only reliable solution. Here is our guide.

Why digitalize quality controls in the food industry?

Despite industrial technological advancements, serious and sometimes fatal incidents have emerged in the food industry in recent years. Cross-contaminations, breaks in the cold chain, bacterial proliferation… All of these health failures have, in some cases, tragically led to the deaths of innocent consumers.

More often than not, the origin of these infections was directly linked to shortcomings in hygiene, cleanliness, and quality control within food industry facilities. These malfunctions are frequently due to the use of manual or outdated compliance tracking methods (paper, logbooks, Excel…).

To overcome the obsolescence of paper and Excel spreadsheets

In France, food industry facilities are facing gradual obsolescence. Beyond sometimes outdated industrial machinery, quality methodologies and procedures are also outdated. Indeed, due to financial challenges in the sector (rising raw material costs, dependence on imports…), some companies struggle to modernize and continue to rely on inadequate paper-based tracking methods. This delay and paper-based traceability have repeatedly shown negative consequences:

- Increased tracking errors, missed control steps, or misinterpretations of the quality procedures to apply

- Lack of visibility over operational workflows, compliance with sanitary protocols, and adherence to acceptable thresholds in food industry quality controls

- Difficulty tracing the origin of an anomaly in case of contamination, with a potential risk of the crisis spreading throughout the production chain

- Damage to brand image and indirect harm to your company in the event of a health issue

To prove and ensure sanitary compliance

The food industry is subject to European legislation known as the « Hygiene package

hygiène », which ensures the safety and quality of products in the sector. Professionals must comply with a number of traceability and control requirements but are free to choose the methods they implement to meet these obligations.

To track, verify, analyze, and manage quality controls in the food industry, digitalization emerges as the only reliable tool:

Tamper-proof audit trail with complete traceability: Digital traceability of food industry quality controls provides a 360° view of all intervention workflows. Photos, dates, completed actions, compliance indicators, secure electronic signatures… every element is digitized within a digital interface. If needed, supervisors can access information in real time or retrace an employee’s workflow. All these data serve as legal evidence in case of disputes or audits.

Safety for consumers and employees: On one hand, digitalizing quality controls in the food industry allows for instant action in case of non-compliance. If a threshold is not met, the anomaly is automatically pinpointed and site managers are alerted within seconds. This proactive management helps contain issues within a limited area and resolve them as quickly as possible. On the other hand, if a health crisis cannot be prevented, digitalization allows tracing the affected products and notifying the concerned populations. Supermarkets, suppliers, and retailers can identify faulty products via serial numbers and remove them from sale before any issue arises.

Cost reduction and financial savings:

Digitalized quality controls in the food industry are a highly effective way to optimize operational workflows and thus reduce operating costs. Unnecessary travel, duplicate tasks, and inefficient interventions are eliminated thanks to intelligent analysis from digital tools. Additionally, digitalization reduces the risk of crises and, consequently, the risk of penalties. Without health scandals, compensation for victims, legal fees, or various litigation costs are no longer an issue.Ecological transition: Digitalizing is an excellent way to eliminate paper from your intervention workflows. In addition to food industry quality controls, all protocols, safety procedures, work orders, and attendance sheets can be fully digitized. All of this directly contributes to reducing your carbon footprint.

- Obtaining certifications: Finally, digitalizing quality controls in the food industry is a prerequisite for various health certifications. Whether at the international, European, or national level, certification bodies often require digital, secure, and encrypted traceability.

What are the quality certifications in the food industry?

As mentioned earlier, the “Hygiene Package” sets the mandatory European standards within the European Union. In addition, companies in the food industry can obtain several health and quality certifications. These recognitions confirm the quality of food industry controls, compliance with environmental criteria, or adherence to ultra-cleanliness reference frameworks. Among the main quality standards in the food industry, we find:

- ISO 9001 – Quality Management: This international certification is the essential quality standard. It aims to acknowledge the implementation of efficient quality processes within the company and attests to the qualifications of the employees who carry them out. In the food industry, ISO 9001 is a necessary validation to prove the quality of food production processes.

- ISO 22000: This other globally recognized ISO standard certifies the processes for controlling food safety in a company. This certification, divided into five sub-references, places strong emphasis on risk analysis, from product manufacturing to the supply chain, as well as their storage and transport.

- FSSC 22000: This standard combines the requirements of ISO 22000 with other specific technical requirements, mainly for large groups.

- IFS Food: This certification confirms product safety and compliance regarding hygiene and cleanliness, especially for suppliers of major retailers.

- HACCP: This mandatory standard applies to the entire sector and ensures proper management of health risks throughout industrial processes.

Other more specific ISO standards relating to microbiology or particle hygiene are also available for companies wishing to apply (ISO 14644, ISO 16140-3, ISO 11133, ISO 8700, ISO 7218). Professional branches in various food industry sectors (wine production, dairy products, aquaculture…) also offer Good Hygiene Practice Guides (GHPG) to support companies on certain certifying aspects.

The best quality control tools in the food industry

Digitalizing quality controls in the food industry necessarily involves adopting a digital tool capable of ensuring digital traceability. Software, mobile apps, sensors, connected devices… There are many options, and your choice will depend on the level of traceability required and your budget. Deploying digitalized quality controls in the food industry inevitably requires a more or less significant investment. In all cases, your solution must allow for two key processes: collecting data related to control compliance and analyzing these indicators.

QMS or MES software

“Quality Management System” (QMS) and “Manufacturing Execution System” (MES) software are tools specifically designed for quality monitoring in industrial environments, including the food industry. Their main strength lies in document management, offering a centralized repository for all quality procedures related to the activity (policies, version control, forms, etc.).

These tools make it possible, among other things, to digitize food industry quality controls and link them to approval workflows. Each validation, modification, or deletion of information is associated with authorized personnel through secure, named interfaces.

Additionally, QMS software offers advanced functionalities for managing quality audits: checklist execution, evidence collection, traceability of findings… These features help track non-conformities detected during inspections, define corrective action plans, and automatically generate reports. Some software specialized in the food industry, such as Qubes, goes even further with options for range management, batch processing, or managing products and weighing processes. Suppliers can even be integrated directly into quality workflows through a dedicated portal.

However, these systems generally lack so-called “operational” functionalities, such as scheduling, task management, or assignment of rounds. They often require integration with an ERP or a dedicated management tool to provide comprehensive and effective oversight.

Management platforms

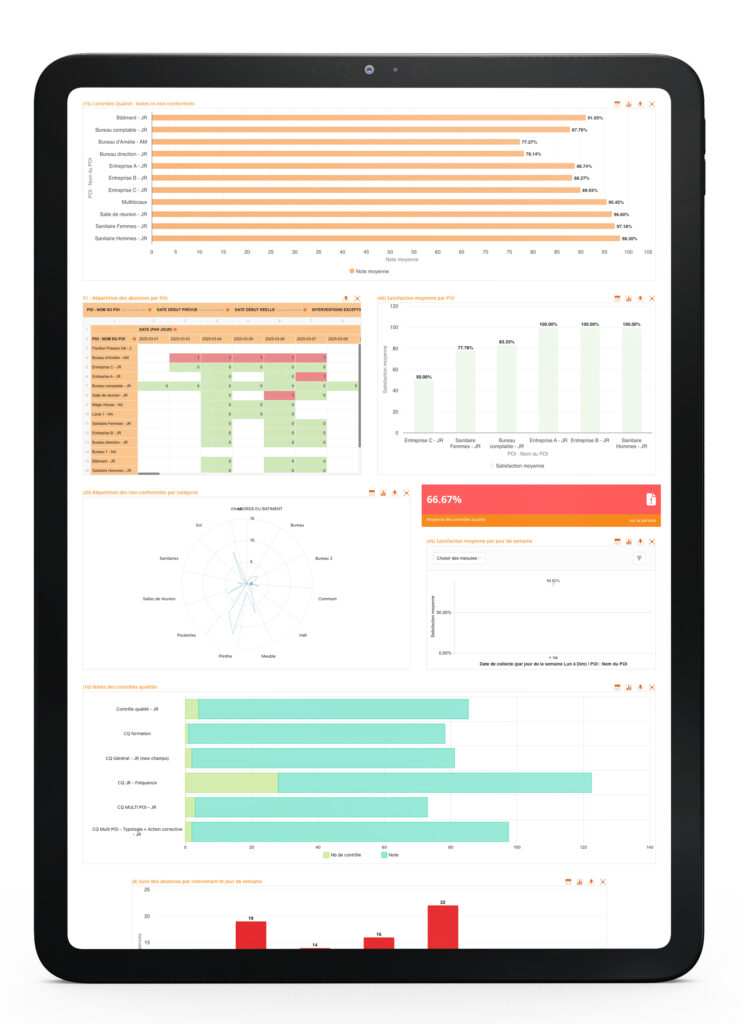

To go further and manage traceability and your food industry quality controls from A to Z, activity management platforms are powerful allies. Beyond the quality aspect, they offer features related to operational management, both for production staff and for quality managers or site directors. Their high level of modularity enables continuous analysis of field data and the intelligent orchestration of information flows.

This type of intelligent tool, like MoveWORK Flow, transforms the intervention workflow of your food industry sites into a transversal and dynamic information-exchange system. Presence, actions, compliance, quality control… every operation recorded in the field can automatically trigger a corrective or complementary action when necessary. For example, when an operator records a temperature deviation on a packaging line, the platform simultaneously alerts the supervisor, locks the affected production area, and initiates the verification procedure defined in the HACCP protocol.

These platforms natively integrate connections with mobile applications, IoT sensors, time-tracking devices, or biometric systems. All data is automatically correlated in dashboards for a comprehensive analysis of situations. Instead of analyzing a parameter in isolation, the tool aggregates information and key performance indicators to deliver an accurate understanding of what is really happening on the food industry site. In practical terms, a quality manager can identify recurring deviations in real time and anticipate preventive actions before an anomaly turns into a non-conformity.

Ultra-cleanliness mobile applications

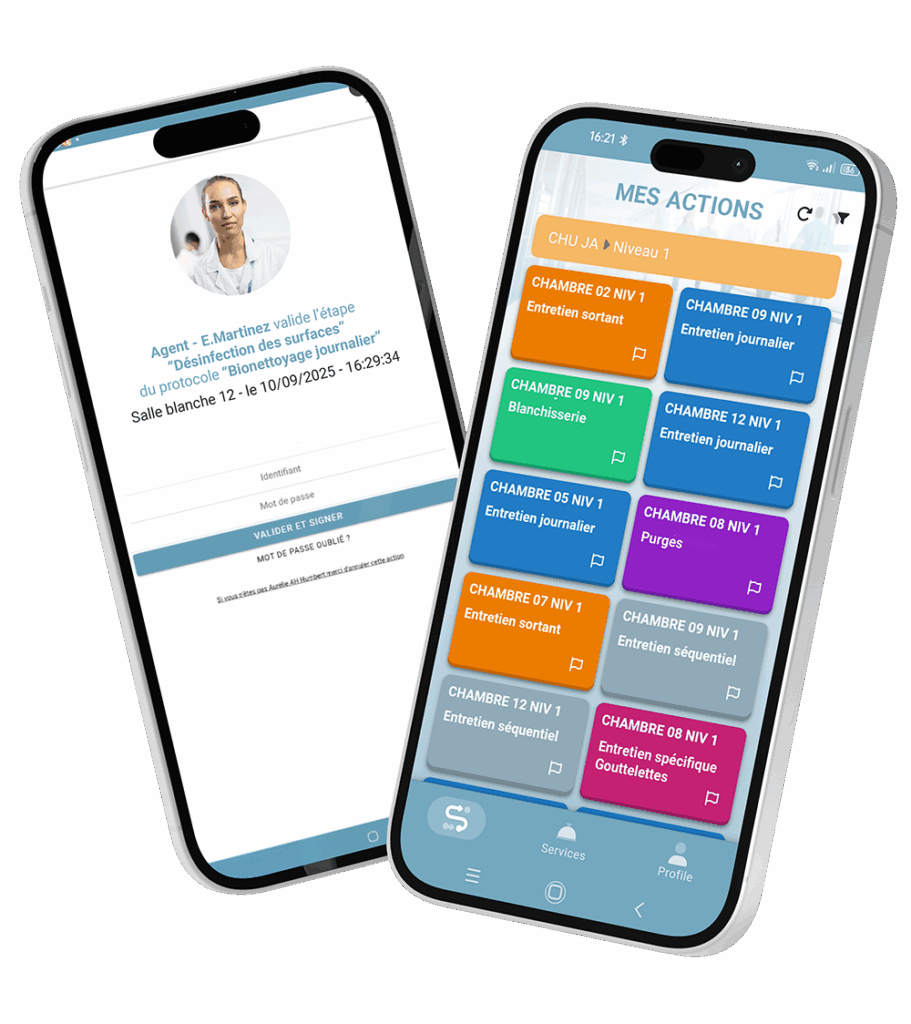

Software and platforms are effective from your office or a dedicated workstation, but in the field, mobility is essential. That’s where mobile applications come in! Available on configured professional devices or even a standard smartphone, they allow you to record actions directly and in real time from the field.

Applications like myMissions Indoor provide secure digital traceability at every step of the intervention process. All actions carried out are recorded and validated through an electronic signature. Thanks to a digital mapping system of your factories or industrial sites, operators can access all applicable protocols depending on the area they are in.

Additionally, authorized managers can perform food industry quality controls directly from the app in just a few clicks. Here again, the intelligent system detects their location and automatically synchronizes

the controls with the applicable scoring grids. No workflow is left to chance! All collected data is traceable and accessible at any time from the MoveWORK Flow platform. In the event of a deviation, the right qualified and authorized person is alerted and receives a tailored action plan to correct the situation.

IoT and connected devices

To complement the data collection process, if your budget allows, IoT sensors are an excellent option. These devices measure, in real time, a wide range of environmental indicators that are essential for ensuring the compliance of food industry products. Humidity levels, CO₂, volatile organic compounds… all these measurements provide you with a comprehensive view of indoor air safety and quality across your production lines.

Thanks to the LoraWan network, connected devices and IoT sensors continuously detect key elements without consuming significant energy. When combined with a platform like MoveWORK Flow, they alert you whenever a threshold is not met or exceeded and allow you to automate all corrective actions related to food industry quality.

The steps to digitalize your food industry quality controls

Digitalization may look achievable in just a few clicks… But in reality, a digital transformation must be prepared step by step. If you rush in headfirst, you have a fifty-percent chance of failing! That’s why it is essential to deploy your project through several progressive phases:

- Understand, analyze, illustrate:

The first stage is an assessment of your current situation. How does your production line operate today? Who are the employees involved in the process? How are quality controls tracked? Every element related to your existing procedures must be identified and documented in a report that will serve as the introduction to your specifications. - Define the need:

Your initial audit will help you identify the gaps in your operational processes and your food industry quality controls. Which steps are not sufficiently traced? What level of security do you need to implement? Who should be authorized? After this analysis, draft a complete set of specifications covering the functional, logistical, and human requirements of your project. This document will guide your choice of solution and save you time in the research phase. - Search for and identify the right tool:

A decisive step in the success of your food industry quality control digitalization project, the search phase must leave nothing to chance. Do not type “quality software” into Google and pick the first tool you see! You must carry out a true comparative analysis of the features of each solution versus your functional requirements. And you know what? Thanks to your specifications, all your needs should now be clearly listed!

This process can be long and tedious, so we recommend limiting your shortlist to 3 or 4 solutions. For each quality tool, check the features, the vendor’s credibility, and all associated costs (subscription, maintenance, training…). With this review, you will be able to build a comparison table listing the strengths and weaknesses of each solution. - Deploy, train, and adjust:

Deployment marks the transition from concept to reality.

Start small, with a test scope, to observe how the solution integrates into your existing working methods. This trial period will help you identify what works well and what needs fine-tuning before rolling the tool out across your entire production line. Once the framework is adjusted, it’s time for training. Each user must understand how to make the most of the tool. The more engaged your teams are, the smoother the transition will be. Finally, keep some flexibility: digitalization is not a fixed, one-time project. Take a step back and adjust as needed.

Digitalizing quality controls in the food industry is not an easy project! Experts, like the MoveWORK teams, can support you throughout your digital transformation.